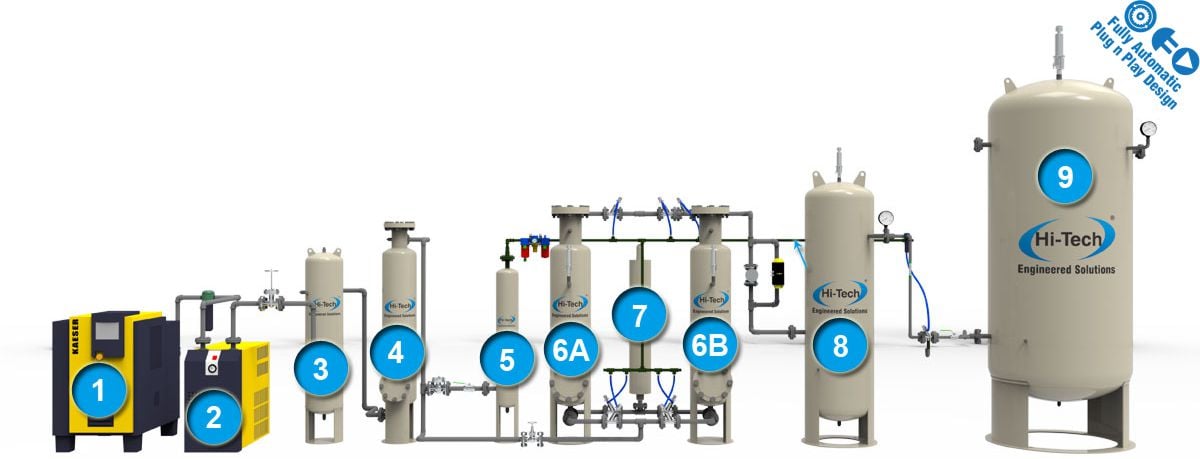

Steps For Pure Nitrogen Generation From Atmospheric Air

- Air Compression

- Air Drying

- Air Buffer Tank

- Trace Oil Particle Filter

- Air Buffer for Automatic valve

- A. Absorbing Tower A B. Absorbing Tower B Flue Gas Vent Silencer

- Nitrogen Surge/Buffer tank

- Nitrogen Storage Tank

Adsorption is a gas separation process whereby the gas molecules adhere to a surface when under pressure. Adsorption allows for the ability to separate specific gasses, such as nitrogen, from compressed air by selecting an adsorbent material which unwanted gases more readily diffuse into. In the case of air-to-nitrogen separation, compressed air is passed through a cylinder containing a Carbon Molecular Sieve as an adsorbent. Oxygen, H2O and CO2 molecules diffuse into the pore structure of the carbon molecular sieve faster than nitrogen molecules, allowing the nitrogen to travel through the carbon molecular sieve column, while the other gases are trapped in the Sieve column.

Once the adsorbent has reached its maximum saturation capacity, the cylinder goes through a depressurisation cycle resulting in near-vacuum conditions inside the cylinder. This results in the by-product gas molecules separating from the adsorbent so they can be flushed from the cylinder making it ready for further use. During the depressurisation cycle the cylinder cannot be used for further nitrogen generation making it unsuitable for applications where a continuous supply of nitrogen would be required.

To ensure the highest purity of nitrogen (up to 99.9995% nitrogen purity can be achieved with PSA Nitrogen generators) and enable continuous, uninterrupted nitrogen production, Pressure Swing Adsorption technology uses two identical Carbon Molecular Sieve columns which are alternately pressurized with compressed air.

When column 1 is pressurized, the non-nitrogen molecules are trapped in the porous carbon molecular sieve material and pure nitrogen travels through the column to be collected in a nitrogen receiver tank. At the same time, the second column is depressurized to atmospheric pressure to vent the trapped contaminant molecules from the column. Then the cycle continues by pressurizing column 2, while column 1 undergoes depressurization. Switching generation between cylinders in this way, with spent cylinders being cleaned whilst another is generating nitrogen, allows for a continuous flow of nitrogen from the generator.